How GPS Tracking Improves Safety on Construction Sites

Safety is a critical concern in the construction industry. A construction site's dynamic and fast-paced environment makes it vulnerable to accidents, equipment failures, and operational hazards. GPS tracking technology has emerged as a valuable tool for enhancing safety measures across construction sites, offering multiple layers of protection through precise equipment monitoring, real-time data, and streamlined communication.

Real-Time Location Monitoring

GPS tracking improves safety by providing real-time location data of construction equipment and vehicles. This ensures that site managers can pinpoint where specific machinery is at any given moment. Knowing the location of heavy equipment, such as cranes, excavators, and bulldozers, allows managers to track potentially hazardous areas and alert workers if machinery moves too close to restricted zones or high-risk areas.

While the system will give real-time alerts if equipment enters an unauthorized area, it is not a proximity sensor that directly alerts the operator of the equipment. However, with this information, site managers can warn of violations and take corrective action with workers and coach them toward better performance.

Geofencing for Safety Zones

Geofencing is a feature in GPS tracking systems that enables site managers to create virtual boundaries around specific areas. These boundaries can be set around high-risk zones, such as excavation pits or regions where hazardous materials are stored. When equipment enters or exits these zones, the GPS system alerts management. A geofence can also be used to identify authorized areas, notifying management of violations possibly before equipment enters an unauthorized area defined by a Do Not Enter geofence.

The proper understanding and use of the various types of geofences can be used in operator coaching. Overall, accidents can be reduced through the use of geofence Entry and Exit rules.

Geofencing is particularly beneficial for large construction sites where it's challenging to maintain constant surveillance over every worker and piece of equipment. This additional level of control helps ensure that workers and machines operate in designated, safe zones, thereby reducing potential safety risks.

Equipment Maintenance Alerts

Construction equipment operates under challenging conditions, often leading to wear and tear. Faulty or poorly maintained equipment can be a significant hazard on the job site, leading to dangerous malfunctions. GPS tracking systems provide automated maintenance alerts based on equipment usage and condition. By tracking data such as engine hours, oil pressure, and/or mileage driven, the system can prompt timely maintenance, preventing breakdowns or malfunctions that could endanger workers.

Furthermore, routine servicing ensures equipment runs efficiently, reducing the risk of accidents caused by equipment failure. Proactive maintenance alerts can also extend the lifespan of machinery, decreasing the likelihood of sudden malfunctions that might lead to safety risks.

Emergency Response and Reporting

In the unfortunate event of an accident, time is of the essence. GPS tracking systems can aid in rapid emergency response by providing the exact location of the incident. Whether it's a vehicle rollover or equipment malfunction, knowing the precise location allows emergency services to respond faster, reducing the potential severity of injuries.

Additionally, GPS tracking systems help generate detailed reports of incidents, which can be used to improve future safety practices. These reports can show where the accident occurred, what equipment was involved, and if there were any violations of safety protocols, enabling companies to analyze the incident and implement preventive measures for the future.

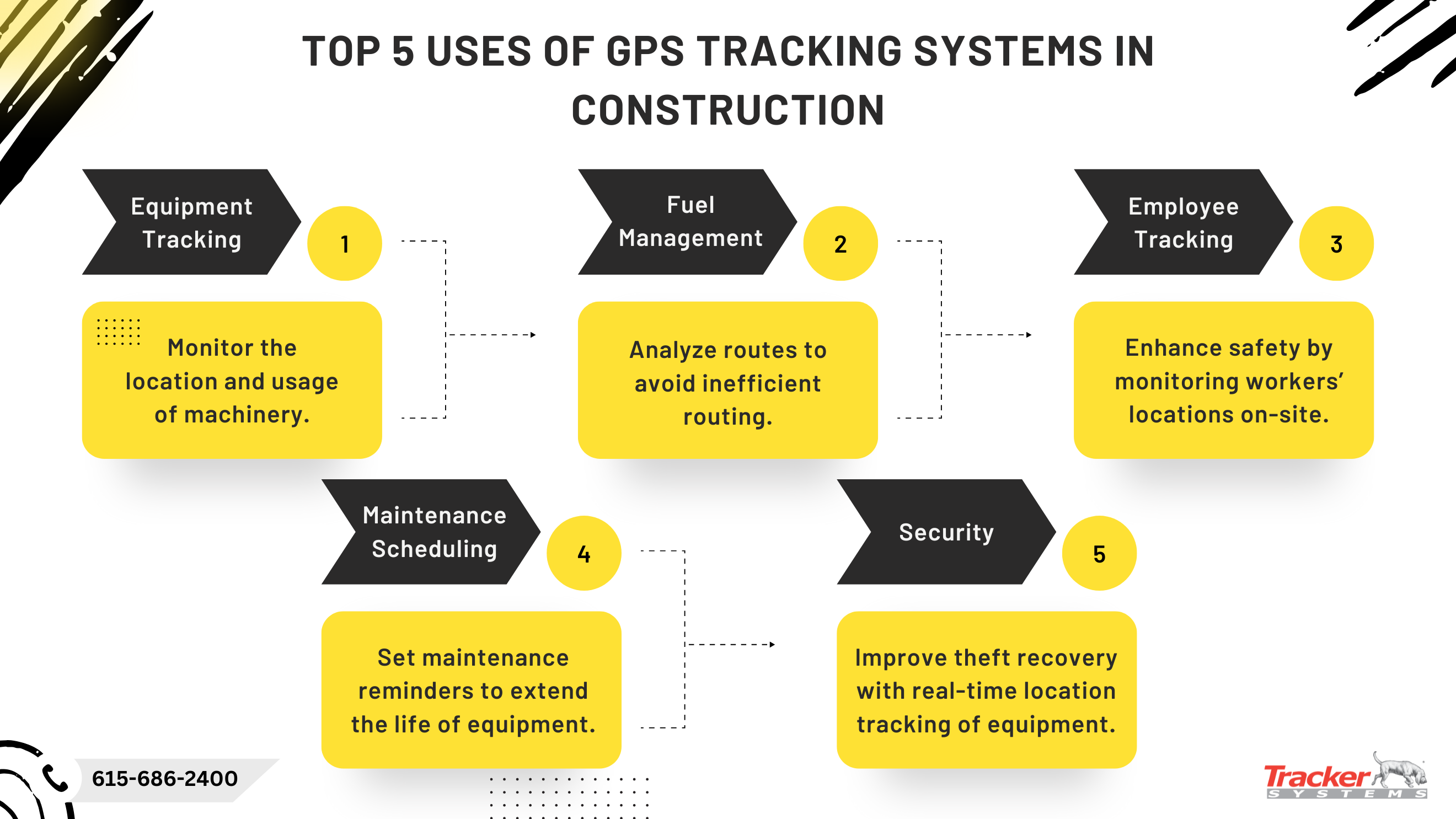

The Main Benefits of Using GPS Tracking for Construction Equipment

GPS tracking systems provide a powerful solution in the construction industry, where managing time, budget, and resources is essential for success. The benefits extend far beyond simple location tracking. These systems enhance productivity, improve cost efficiency, and ensure smoother operations on job sites.

Improved Asset Management

GPS tracking systems allow for comprehensive asset management by providing real-time data on the location and condition of construction equipment. This visibility ensures that equipment is used where and when needed most, preventing underutilization or misallocation of resources. Project managers can quickly locate idle equipment and reassign it to areas where it is required, maximizing productivity and efficiency.

Additionally, by knowing the exact location of each piece of equipment, managers can prevent delays caused by misplaced, lost, or stolen machinery. For construction projects operating on tight schedules, this improved asset management can significantly reduce downtime and keep the project moving forward without unnecessary interruptions.

Cost Savings through Fuel Efficiency

Fuel consumption is a significant expense in the construction industry, especially for heavy machinery that operates for long hours. GPS tracking systems monitor vehicle and equipment movement, idle times, and driving behavior to identify areas where fuel consumption can be optimized. Companies can reduce fuel costs by reducing idle time and improving operational efficiency.

For example, if a piece of equipment is idling for long periods, the system can issue alerts to shut it down or to coach operators at a later date. Over time, these small adjustments can lead to significant fuel cost savings, directly impacting the project's overall profitability.

Enhanced Job Site Productivity

GPS tracking allows managers to streamline operations by keeping track of all equipment on-site. They can deploy resources where they are most needed, avoiding delays caused by equipment bottlenecks or miscommunication. GPS tracking systems also provide insights into equipment utilization rates, allowing for more effective scheduling and allocation of resources.

With the ability to monitor equipment in real-time, project managers can ensure that every piece of machinery operates efficiently. This increases job site productivity, as workers have the tools they need readily available when needed, reducing downtime and delays.

Reduced Insurance Costs

Insurance companies recognize the benefits of GPS tracking systems in reducing risks on construction sites. GPS tracking can lower the likelihood of accidents and claims by improving safety, preventing theft, and enabling better maintenance. This often results in reduced insurance premiums for construction companies implementing these systems.

Furthermore, having detailed GPS data can help resolve insurance claims more quickly in the case of an accident or equipment theft. This reduces the financial burden on construction companies and ensures that projects can continue with minimal disruption.

How GPS Tracking Helps in Preventing Theft of Construction Equipment

Construction equipment theft is a significant problem in the industry. Heavy machinery is a prime target for thieves due to its high value and ease of resale. Construction sites' remote and often unsecured nature makes them vulnerable to theft, leading to costly delays and financial losses. GPS tracking systems are a powerful theft deterrent and provide quick solutions to recover stolen equipment.

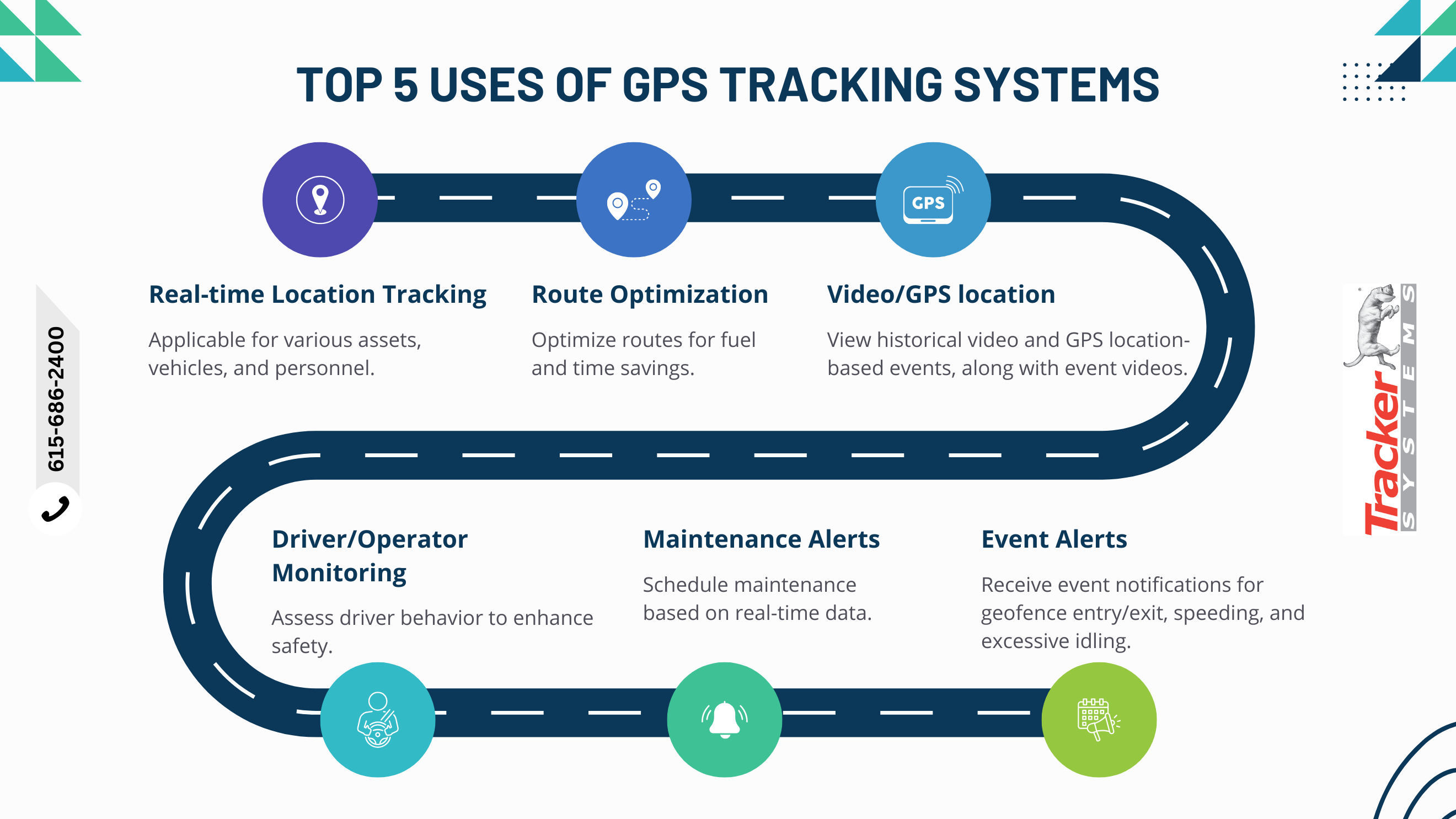

Real-Time Location Tracking

One of the most effective ways GPS tracking helps prevent theft is through real-time location monitoring. Once a GPS tracker is installed on a piece of equipment, its location can be tracked continuously, even when the machinery is off-site or stored in remote locations. If an unauthorized movement occurs, such as equipment being moved outside working hours or beyond the designated area, the system immediately alerts the construction manager or security personnel.

This instant notification allows for a quick response, whether calling law enforcement or remotely disabling the equipment if that feature is available. Real-time tracking not only helps prevent theft but also aids in swiftly recovering stolen equipment.

Geofencing for Theft Prevention

Geofencing is another valuable feature for preventing equipment theft. By creating virtual boundaries around the construction site or storage yard, site managers can receive alerts whenever equipment crosses these boundaries without authorization. For instance, if equipment is moved outside the site after working hours, an immediate alert is triggered, allowing the manager to take prompt action.

These geofences can also be set up around the perimeter of a project, ensuring that equipment remains within the designated area during operation. This helps mitigate the risk of equipment being stolen or used for unauthorized purposes outside the site.

Recovery of Stolen Equipment

In the unfortunate event that equipment is stolen, GPS tracking systems make recovery much more feasible. Law enforcement can use the data from the tracking system to locate the stolen machinery, often before it has been moved too far from the site. This rapid recovery reduces the financial loss of stolen equipment and helps prevent costly project delays.

GPS tracking systems are so effective at deterring theft that many construction companies have experienced reduced instances of theft simply by installing the systems on their equipment. Knowing that equipment is monitored in real-time strongly deters thieves.

Historical Data and Reporting

In addition to real-time tracking, GPS systems keep historical records of equipment movement. These records can provide valuable evidence for law enforcement and insurance claims if theft occurs. The system logs all movements, showing exactly when and where the equipment was last used, helping to build a timeline that can be crucial in recovering stolen assets.

Detailed data on equipment movement also helps prevent internal theft or misuse by workers. If machinery is used outside of authorized hours or locations, GPS tracking provides a clear record, ensuring accountability at all levels.

Features to Look for in a GPS Tracker for Construction Equipment

Choosing the right GPS tracker for construction equipment is crucial to maximizing the benefits of this technology. Several key features should be considered when selecting a GPS tracking system to ensure it meets the specific needs of your construction site and machinery.

Durability and Weather Resistance

Construction equipment operates in harsh environments, often exposed to extreme temperatures, dust, rain, and other challenging conditions. To withstand these elements, a GPS tracker must be durable and weather-resistant. Look for rugged, waterproof systems built to handle a construction site's physical demands. Ensuring the tracker can function in all weather conditions and environments is vital for consistent performance.

Real-Time Tracking and Alerts

Real-time tracking is essential for construction sites, where equipment is constantly moving. The GPS system should offer instant updates on the location and status of all machinery. In addition to location tracking, the system should provide real-time alerts for specific actions, such as when equipment moves outside a geofenced area or is operated during unauthorized hours.

Real-time alerts allow for immediate responses, whether to prevent theft, reduce fuel waste, or enhance safety. The ability to set customized alerts based on specific triggers ensures that site managers can monitor equipment activity closely without constantly checking the system.

Geofencing Capabilities

Geofencing is a critical feature for construction sites. It enables managers to create virtual boundaries around designated areas. When equipment enters or exits these areas, the system triggers an alert. This feature helps prevent theft, monitor safety, and ensure that machinery stays within authorized zones.

Ensure that the GPS tracker allows for flexible geofencing. This means you can create custom boundaries that align with your site’s unique layout. Adjusting these boundaries as the project progresses is also beneficial for managing site logistics and safety protocols.

Maintenance Alerts and Performance Monitoring

One key benefit of GPS tracking systems is their ability to monitor construction equipment performance. Look for systems that provide maintenance alerts based on engine hours, fuel consumption, and other performance metrics. Regular maintenance prevents costly breakdowns and ensures the equipment is always in optimal working condition.

Some GPS tracking systems also offer diagnostic reports, helping to identify potential issues before they become significant problems. This proactive maintenance feature can save time and money by preventing unscheduled downtime due to equipment failure.

Battery Life and Power Options

Battery life is another important consideration, especially for equipment that may be idle for extended periods. A GPS tracker with a long battery life or alternative power options, such as solar charging, ensures that the system remains operational even when the machinery is not in use.

For infrequent equipment, consider trackers with power-saving modes or systems that automatically switch to a low-power state when idle. This helps extend battery life while providing location data and alerts when necessary.

How GPS Tracking Optimizes Equipment Utilization in Construction

Maximizing the utilization of construction equipment is critical to improving overall project efficiency and profitability. GPS tracking systems are crucial in optimizing equipment use by providing valuable insights into how machinery is operated, where it is located, and how often it is used.

Real-Time Equipment Monitoring

GPS tracking systems give site managers real-time data on equipment usage. This allows them to identify underutilized machinery that is better deployed elsewhere on the site. By clearly understanding equipment availability, managers can ensure that machinery is distributed effectively across the project, minimizing downtime and preventing resource bottlenecks.

For example, if a piece of equipment is idle for long periods, it may be reassigned to another part of the project where it is needed. This ensures that all available resources are used efficiently, accelerating project timelines and reducing costs.

Reducing Idle Time and Downtime

One of the most significant contributors to inefficiency on construction sites is idle equipment. Whether due to poor scheduling, delays, or miscommunication, idle equipment represents wasted time and money. GPS tracking systems help identify patterns of idle time, enabling managers to address the underlying issues causing delays.

By reducing idle time, construction companies can improve productivity and ensure that projects stay on schedule. GPS tracking systems can also detect equipment malfunctions or breakdowns early, allowing for swift repairs and minimizing downtime.

Optimizing Fleet Management

For large construction companies that manage a fleet of vehicles and machinery, GPS tracking systems offer invaluable insights into fleet management. These systems provide data on how often each piece of equipment is used, allowing managers to make informed decisions about leasing, buying, or selling machinery.

By understanding their fleet's usage patterns, companies can avoid over purchasing equipment that may sit idle or underutilized. Conversely, they can identify machinery that is frequently in demand and may require additional units. This data-driven approach to fleet management helps companies reduce unnecessary expenses while ensuring they have the necessary resources to complete projects efficiently.

Fuel Consumption and Route Optimization

Fuel costs are a significant operational expense in construction. GPS tracking systems can monitor fuel consumption and driving routes, helping to optimize fuel efficiency. By analyzing route data, managers can identify more efficient paths for equipment and vehicles, reducing travel time and fuel usage.

For example, if trucks take inefficient routes to transport materials across the site, GPS tracking can suggest alternative routes that save time and fuel. Over time, these optimizations lead to significant cost savings, improving the project's overall profitability.

GPS tracking systems have become indispensable in the construction industry, offering significant benefits across safety, cost savings, productivity, and equipment management. From preventing equipment theft to optimizing fleet usage and enhancing job site safety, GPS tracking provides construction companies with the tools they need to operate efficiently and profitably. By choosing the right system, construction companies can ensure that their equipment is always used to its full potential while reducing risks and enhancing site safety.

Recent Posts

-

The Advantages of Using GPS Trackers for Delivery Services

Why Delivery Services Rely on Tracking More Than Ever In the past decade, delivery services, whether …Sep 1st 2025 -

Using GPS Trackers to Improve Business Efficiency

Managing mobile assets, whether a fleet of delivery vans, construction equipment, or service vehicle …Sep 1st 2025 -

How to Choose the Right GPS Tracker for Your Needs

How do you ensure your car, trailer, or heavy equipment stays secure and easily located? In today’s …Jul 24th 2025